Oil flow indicator is a safety device which indicates the flow of liquid in pipeline and gives a signal through making the mercury switch on failure of forced circulation of liquid in pipeline.

The device perform the following functions

Oil flow indicators are mainly designed as a safety device considering the need for an electrical signal on the failure of forced circulation of liquid in the pipe line. The switch will operate if the flow drops near to 70 % to initiate precautionary system.

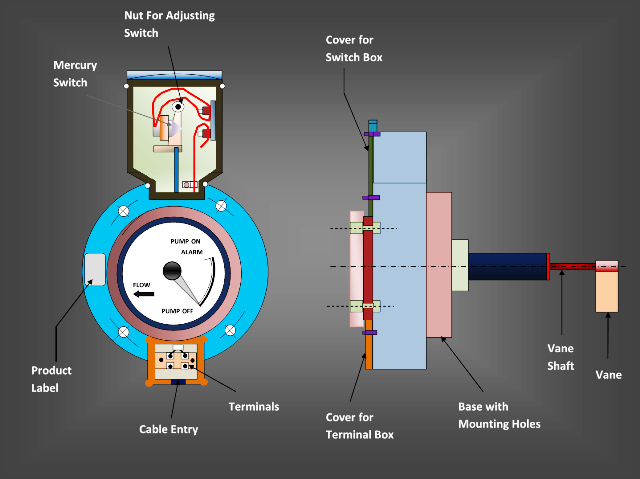

A suspended vane is used as sensor. Its surface is kept at a right angle to the direction of flow. When liquid starts flowing through the pipe, the vane gets deflected along with vane shaft. This deflection is employed to indicate flow inside the pipe and to operate mercury switch as follows.

A pair of permanent magnets is used as glandless coupling. The driving magnet is connected with a vane and therefore it rotates with the vane and remains in the liquid, The follower magnet, separated by a non-magnetic wall, is kept outside in air and acquires a position corresponding to the driving magnet. The follower magnet carries a pointer and a cam. The pointer is set to read full flow and the cam is set to operate the switch when flow drops near to 70%. The switch position can be readjusted if required at site. A return spring is used which acts in the opposite direction of flow. Hence, any steady position of the pointer is the result of equilibrium of force due to impinging liquid on the vane, spring tension & weight of vane. The pointer may not remain steady because the flow may not necessarily be laminar. The size and shape of vane and tension on return spring are adjusted to suit specified full flow. The vane occupies very small area out of the full cross section of pipe at the No-Flow position. At full flow it becomes almost parallel to flow. Hence, there is practically no head –loss across Flow Indicator.